Overview

BigThinkCode developed a cutting-edge smart port management system powered by the Eartheon Digital Twin Platform. This solution integrated IoT technology, machine learning (ML) models, and a Generative AI-based search system to centralize data, optimize port operations, and provide actionable insights for decision-making.

At its core, Eartheon’s platform uses a schematic knowledge graph and ontology mapping with business logic and intuitive search, ensuring seamless data connectivity, intelligent insights and future scalability.

The foundation of this solution was a robust and scalable reference architecture that enabled seamless integration, real-time data processing, and enhanced decision-making capabilities.

Key Challenges Addressed

Fragmented Data Sources

Port operations relied on diverse data sources from IoT sensors and legacy systems, resulting in silos that made unified data access challenging.

Lack of KPI Monitoring

The absence of a comprehensive system to monitor Key Performance Indicators (KPIs) hindered real-time operational insights and decision-making.

Operational Delays

Disconnected systems and manual data retrieval processes caused delays in vessel scheduling, cargo handling, and incident responses.

Absence of a Unified Command and Control Center

Without a central system to coordinate vessels, cargo, and environmental operations, situational awareness and operational efficiency were significantly compromised.

Scalability and Usability Challenges

Existing systems struggled with scaling up to handle growing data volumes and lacked user-friendly interfaces for rapid decision-making.

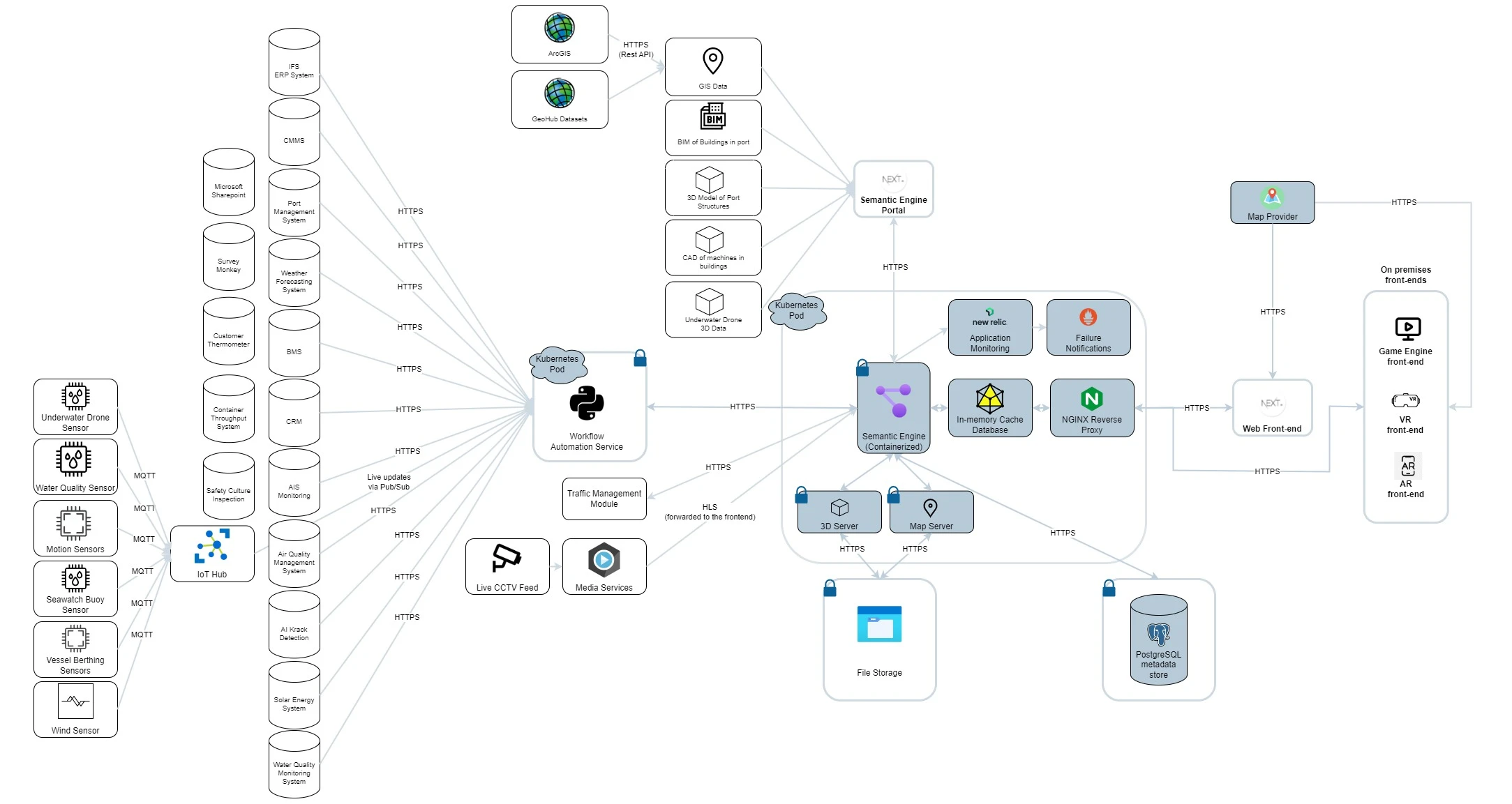

Reference Architecture Overview

Key Components of the Solution

IoT Layer:

IoT sensors provided real-time data for vessel movements, cargo conditions, and environmental factors.

Data Connectivity and Processing

Kafka was implemented for real-time Change Data Capture (CDC), enabling rapid ingestion and synchronization of high-volume sensor data.

Centralized Data Server

A single repository served as the primary data hub, supporting historical analysis and compliance requirements.

Eartheon Semantic Engine

The core of the platform was its schematic knowledge graph and ontology mapping, connecting disparate data sources with business logic for a holistic view of operations.

Unified API Gateway

Provided seamless access to connected systems, supporting the Eartheon Digital Twin platform and ensuring consistent interaction across modules.

Eartheon Digital Twin Platform

Integrated ML models and predictive analytics to deliver insights for operational optimization and anomaly detection.

Unified Command and Control Center

Offered a centralized hub for monitoring KPIs, enabling stakeholders to coordinate portoperations efficiently.

GenAI-Powered Search System

Simplified data exploration with natural language queries, allowing users to access insights and generate reports effortlessly.

Solution Implementation highlights

KPI Monitoring and Unified Command Center

Eartheon’s platform addressed the disconnect in data by leveraging its knowledge graph to integrate IoT sensor data, operational systems, and business logic. A unified command control center was established, providing real-time KPI monitoring across vessels, cargo, and environmental operations.

Data Centralization and API Integration

Centralized data storage and a unified API ensured real-time access to accurate and synchronized information for all operational modules.

Advanced Analytics

ML models were implemented for cargo stacking optimization, vessel scheduling, predictive maintenance, enhancing decision-making capabilities.

Enhanced User Accessibility

A GenAI-based search interface simplified complex data queries, empowering users with actionable insights via natural language interactions.

Supply chain optimization

Our platform also supports supply chain optimization through Real-Time Transportation Visibility Platforms, enhancing movement within high-speed supply chains. By monitoring yard traffic, we empower intelligent controllers to minimize yard wait times, improve traffic flow within ports, and ensure smooth operations from gate check-in all the way to final placement.

The focused supply chain optimization can lead to cost reductions of up to 25%, more than double the savings from other operational improvements.

Outcome

Operational Efficiency

25% reduction in vessel berthing delays due to real-time KPI tracking.

30% improvement in cargo stacking and unloading efficiency.

20% reduction in response times for incidents such as fire or cargo spillage.

Enhanced Decision-Making

Centralized KPI monitoring improved decision-making efficiency by 40%.

Predictive analytics prevented operational disruptions, achieving 92% accuracy in anomaly detection.

User Experience and Accessibility

GenAI-powered search reduced data query times by 35%, enhancing operational usability.

Impact of Eartheon’s Digital Twin Platform on Smart Port Operations

30% improvement in cargo management, streamlining stacking and unloading processes.

92% precision in anomaly detection, fostering operational stability and averting disruptions.

35% improvement in query speed, boosting usability and access for stakeholders.

Talk to us for more insights

What more? Your business success story is right next here. We're just a ping away. Let's get connected.